Industrial Predictive Maintenance

Soralink's predictive maintenance solution uses AI and Machine Learning to analyze industrial equipment data, preventing failures before they happen.

Start reducing your maintenance costs now with our trial period!

Reduce your maintenance costs with Soralink's trial offer! Enjoy 6 point sensors for the first 6 months of predictive maintenance. This trial will show you the value of a long-term commitment.

As our customer testimonials reveal, many businesses are suffering high costs due to preventable breakdowns. Interested in finding out how predictive maintenance can benefit your production? Simply click the button below, and we’ll be happy to help.

Why Choose Predictive Maintenance?

Equipment breakdowns can cause annual production losses of 2% to 12%, impacting productivity.

Soralink's predictive maintenance sensors help minimize these losses by alerting you before a failure occurs, enabling timely maintenance without the disruption of unplanned shutdowns.

The 3 Components of Soralink Solution Predictive Maintenance

Component 1

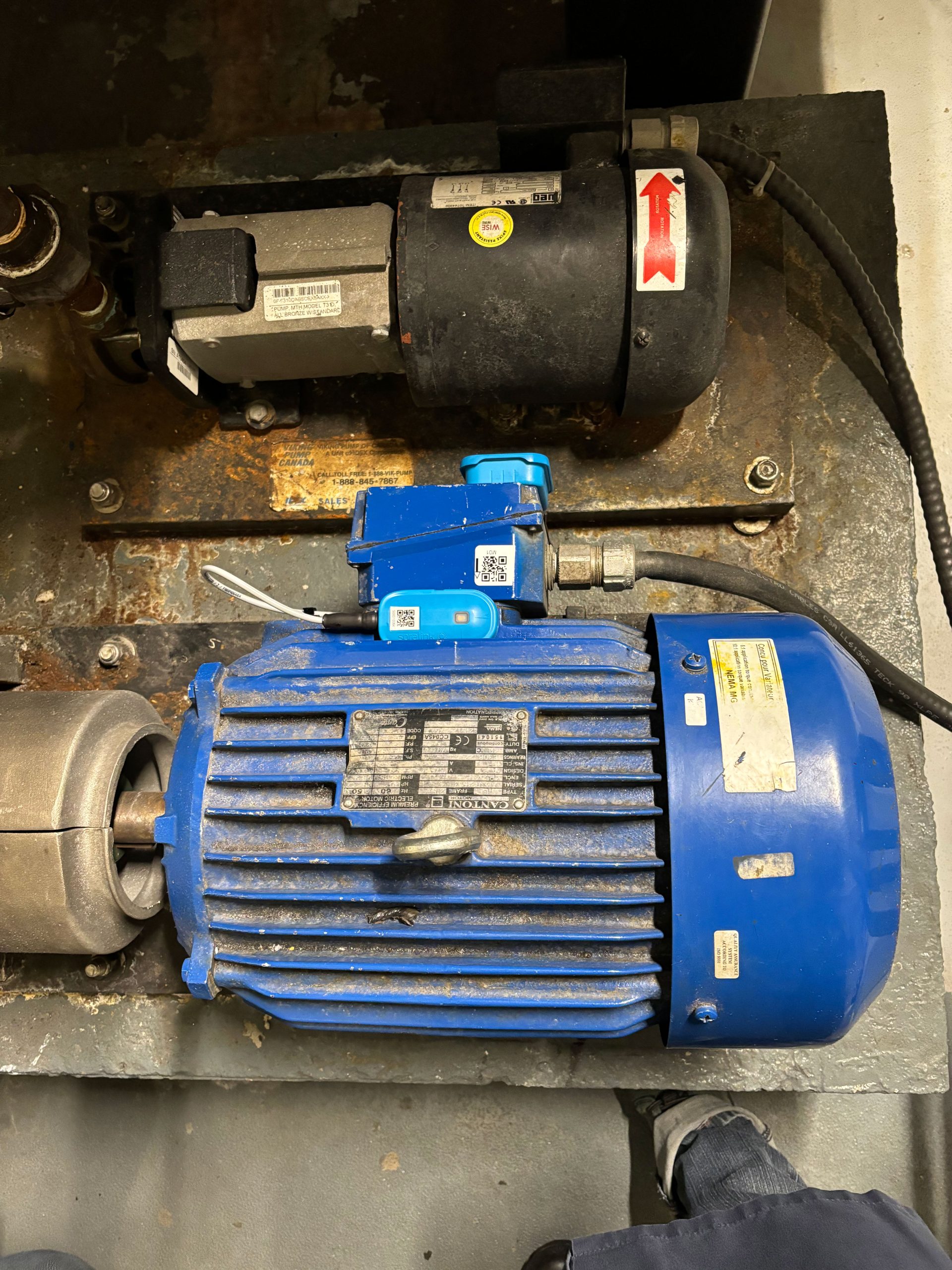

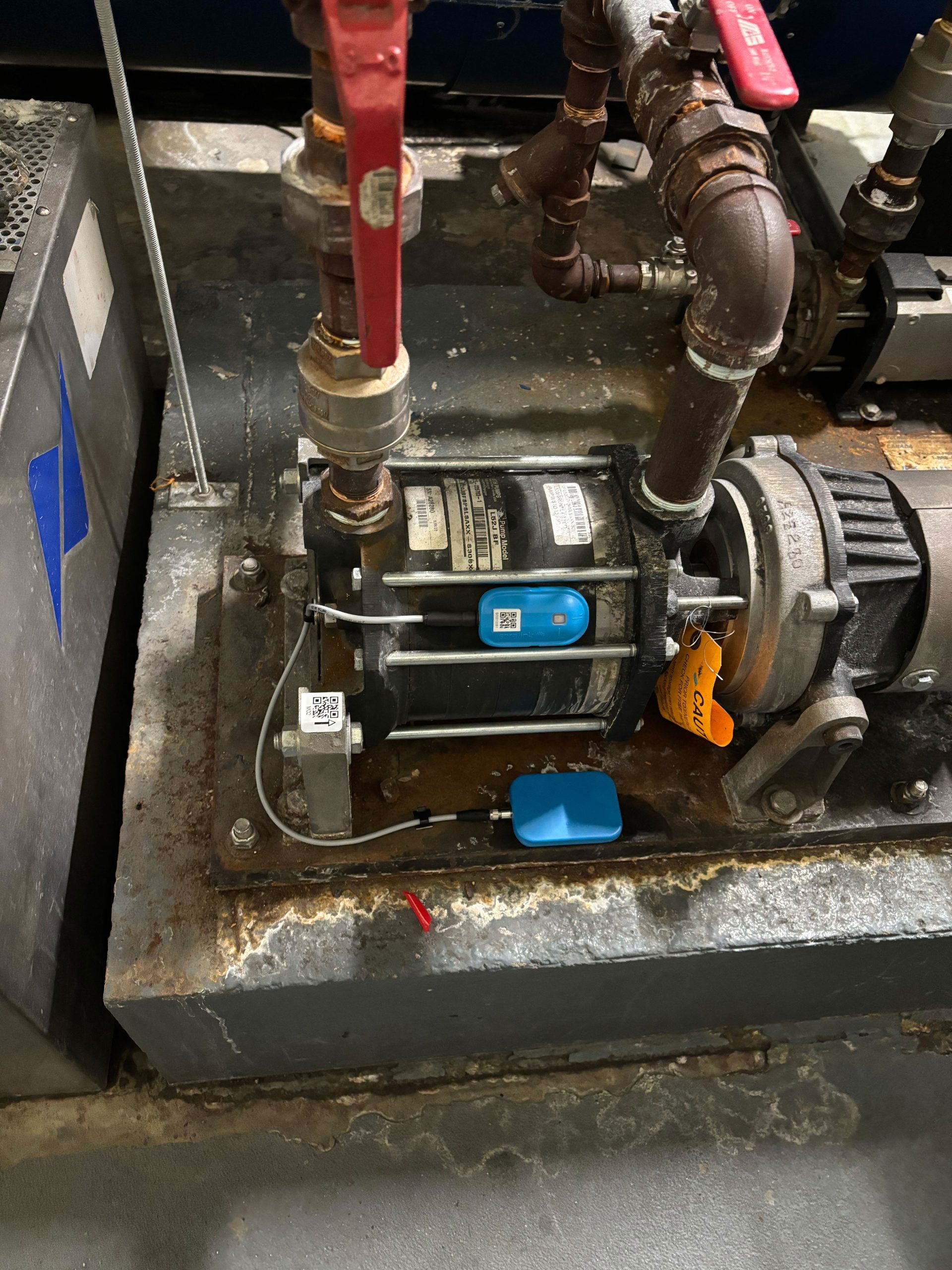

Predictive Maintenance Sensors

Our sensors operate autonomously, requiring no manual interaction. We've combined vibration, sound, and temperature sensors into a single, compact unit for easy installation and data integrity. These sensors are robust, discreet, and built to withstand harsh environments.

They continuously monitor key data points such as vibration, engine speed, temperature, and noise levels. To ensure reliable connectivity without relying on your local network, Soralink Solution utilizes a secure 5G network.

Component 2

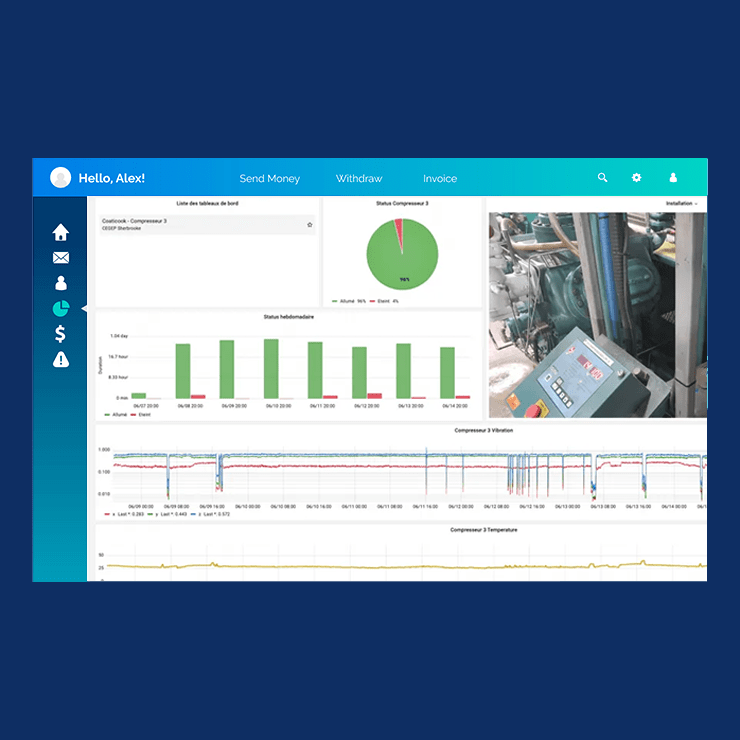

Dashboard

Data from your equipment is collected and analyzed by sensors, then presented on an intuitive dashboard. The dashboard alerts you to potential defects, allowing for timely predictive maintenance, and provides bi-monthly reports on overall machine health.

Clear graphs and charts help you prioritize actions and schedule maintenance efficiently. Our algorithm continuously learns from your machines, improving its ability to predict breakdowns with increasing accuracy, all without human intervention.

Component 3

Artificial Intelligence

Our sensors leverage AI to detect early signs of equipment failure, preventing breakdowns and shutdowns.

What sets Soralink apart is that our machine learning algorithm is embedded directly in the sensors, ensuring a simple and cost-effective solution.

The analysis engine is highly optimized and adaptable to various machines, learning from similar equipment to identify warning signs even faster.

- Our offers

The 3 Types of Maintenance

Reactive, Preventive and Predictive

Reactive

maintenance

Objective

Restart the stopped machine as soon as possible.

Reason for action

Machine/System Breakdown

Type of service

Repair of parts

Risks of unplanned downtime

++++++

Impact on production

High

Uncertainties in Asset Management

High

Soralink predictive maintenance

Objective

Prevent the machine from stopping

Reason for action

Anomaly alerts through real-time monitoring

Type of service

Schedule maintenance

Risks of unplanned downtime

None

Impact on production

Very small impacts

Uncertainties in Asset Management

Very low

Preventive maintenance

Objective

Prevent machine going offline

Reason for action

Inspection programmée/ périodique

Type of service

Schedule/Periodic

maintenance

Risks of unplanned downtime

+++

Impact on production

Small impacts

Uncertainties in Asset Management

Medium

More than predictive maintenance costs

All manufacturers are well aware of the disadvantages directly linked to equipment breakdowns, such as loss of resources and time. Soralink's solution goes far beyond saving on maintenance costs. With our easy-to-install, easy-to-use product, you'll increase the visibility and predictability of your critical machines, reduce stress on your teams, become a reliable partner for your customers, and reduce your overtime budgets.

By becoming pro-active in all aspects of your predictive maintenance, all your production processes will benefit.

We offer a customized managed service, providing not only hardware and software, but also continuous monitoring of your equipment using proven predictive maintenance algorithms. Your maintenance and reliability team doesn't need to log on to our system every day to manage thresholds.

Customers typically achieve a return on investment (ROI) in less than 3 months when they identify the critical equipment causing the most downtime.

No, we offer a turnkey subscription solution. This includes the cost of hardware, software and ongoing monitoring. However, travel expenses may apply if the site is far from our head office in Montreal, Quebec.

The minimum trial period is 6 months to cover part of our fixed costs associated with establishing a new relationship.

Integration includes 1 hour of training to use our dashboard and manually set certain thresholds. Vibration analyst support is available 7 days a week.

- FAQs

Frequently Asked Questions

Check out our Technical Support FAQ to learn how we efficiently handle your technical issues, ensuring you receive the support you need to stay productive and focused.